Demisters are gas-liquid separation devices used to remove mist entrained in gas. They can be installed inside the tower or at the upper part of the tower, According to the demisting requirements, one or two layers of demister elements can be set in the tower. They are suitable for occasions where demister elements often need to be cleaned, overhauled or replaced.

The applicable gas velocity (calculated by the effective cross-sectional area of the gas passing through the demister) range of demisters is 2.5 - 4.5m/s; the suitable gas velocity for the sulfuric acid industry is 3 - 4m/s. The mist particle size in the gas is > 5μm, and the mist concentration is ≤ 100g/m³. For the sulfuric acid industry, when the gas velocity is 3.2m/s and the mist particle size is > 5μm, the demisting efficiency is > 98%.

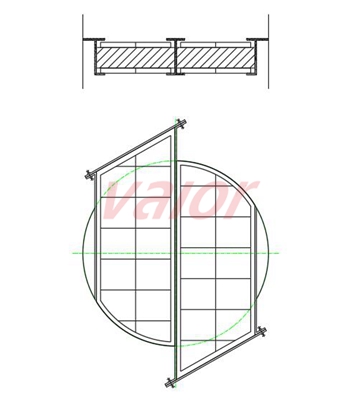

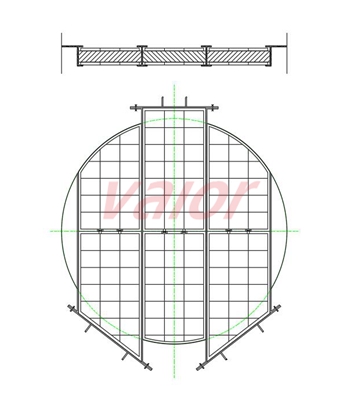

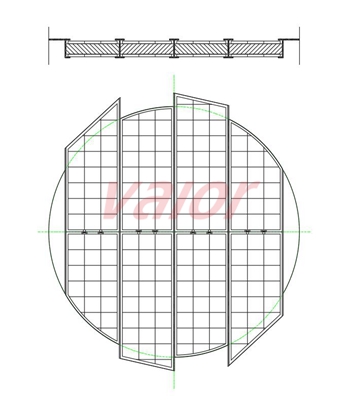

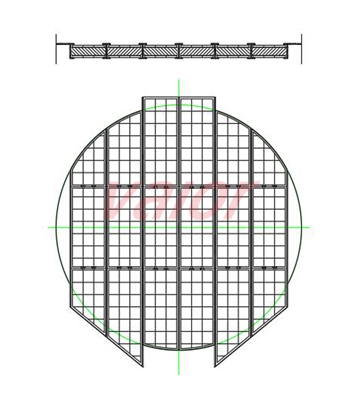

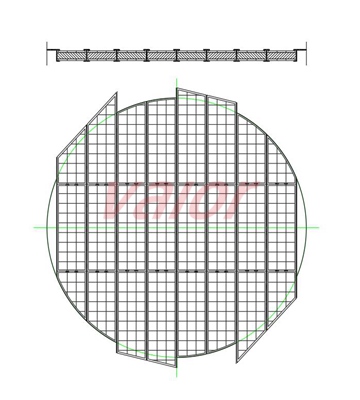

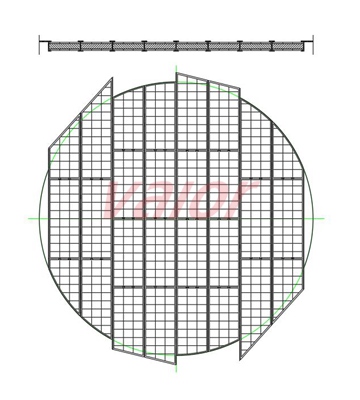

A demister is composed of several rectangular mesh blocks combined with spacer rods and gratings to form demister elements, which are then installed into a cylinder with guide rails and sealing plates to form a drawer - type wire mesh demister. The mesh blocks of the demister are made up of dozens of layers of flat - laid corrugated wire mesh layers. The thickness of the mesh blocks is divided into two types: 100mm and 150mm. The demister elements can be directly inserted into or pulled out along the guide rails through the installation and disassembly openings on the tower body. The number of drawers and the drawer dimensions of demisters with different nominal diameters can be referred to the following figure (Some drawer covers are omitted).

Welcome to contact Mr. Li An for FREE drawing support and more details!

For your convenience: Cell / Whatsapp: +86 13333087316 Email: ann@chinademister.com