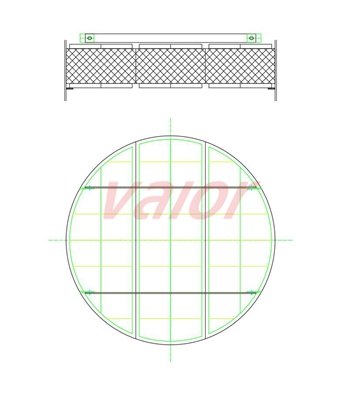

This wire mesh demister has a diameter of 1200 mm. The mesh thickness is 200mm, with mesh density 168 Kg/m3. The void fraction ε is about 97.9%. The specific surface area is about 368 m2/m3. We made this demister into 3 parts, all in SS304 material.

Popular Demister Mesh Types

| No. | DENSITY (Kg/m3) | Void Fraction (%) | Surface Area (m2/m3) | Application |

|---|---|---|---|---|

| 1 | 80 | 99.0 | 175 | Equal to 931. It is used for the case that velocity is big, small pressure drop is required, or collection of big particles or high efficiency is not required. |

| 2 | 128 | 98.4 | 430 | Equal to 326. Higher efficiency, less pressure drop. Because it uses thinner stainless steel wire. |

| 3 | 144 | 98.2 | 316 | Equal to 431. It is extensively used for petrochemical plants. Pressure drop is quite small and efficiency is 90-99%. |

| 4 | 168 | 97.9 | 368 | In HG/T 21618-1998, it is standard mesh type, that is mostly used, with type code "SP". |

| 5 | 193 | 97.6 | 423 | Equal to 421, high-efficiency style. When the gas velocity is 1-5m/s. The mist eliminating efficiency can be 98-99% for 5-10 um particles. |

We also manufactured supports for this demister. There is support ring at bottom, which were divided into small pieces and needs to be welded to the tower wall before installation. These two hold down beams are at top of the demister. Its ribs need to be welded beforehand, too. But the beam itself is fastened by bolts and nuts, after the demister is put in position. When the demister diameter is bigger, support beam shall be considered. And the hold down beam can be angle steel instead of simple flat plate. Infact there are various types of supports in practice. Welcome to tell us the right support type you want.

→

→

Welcome to contact Mr. Li An for FREE drawing support and more details!

For your convenience: Cell / Whatsapp: +86 13333087316 Email: ann@chinademister.com