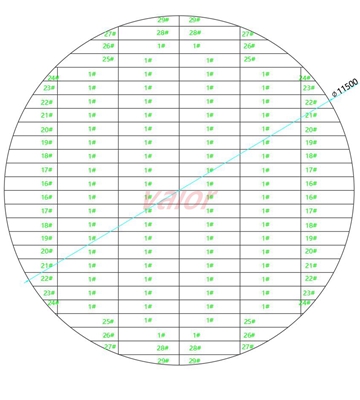

In coal-fired thermal power plant, a desullfurization column or SO2 absorption tower usually has large size in diamter. In this case it is 11500mm in diameter. Once we made OD 15000mm demister pads.

Demisters for power plant desulfurization towers serve as key barriers to eliminate moisture-laden flue gas droplets, specifically engineered to withstand acidic environments from sulfur dioxide (SO₂) absorption. Constructed with acid-resistant alloys (e.g., 316L stainless steel or Hastelloy), their multi-layer wire mesh structure efficiently captures liquid particles while resisting corrosion and abrasion from fly ash. Designed for high-volume flue gas systems, these demisters have low pressure drop. They can ensure continuous operation in wet flue gas desulfurization (WFGD) processes without compromising emission standards.

→

→

The structure of the wire mesh demister includes a roll structure and a layer structure, and the layer structure is currently commonly used. It is laid layer by layer with crimped knitted wire mesh, reaching the specified number of layers. A grid is placed on top and bottom of each layer, and the mesh pad is laminated to the required mesh height of the demister. It is fixed into a whole piece with spacer rods and / or tie wires. The shape and size of the mesh pad are determined by the design calculation of the wire mesh demister, equipment conditions, and manhole size.

Welcome to contact Mr. Li An for FREE drawing support and more details!

For your convenience: Cell / Whatsapp: +86 13333087316 Email: ann@chinademister.com