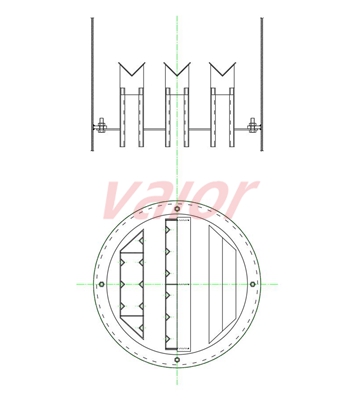

This kind of gas-liquid distributor can be used in structured packing (perforated plate corrugated packing) towers and random packing towers with diameters from DN600 to DN6000mm. It is installed at the top of the packed tower and the upper part of other packing layers. The liquid deflector cap is an optional item. Without it, the distributor can only be used for liquid distribution and has limitation in installation positions. Only the full type with liquid deflector cap can be used for gas and liquid distribution, and freely positioned on top of either packing layer.

Trough-type gas and liquid distributor drip point density: (95±10) /m².

Typical liquid flow rate: 2~50 m³/(m²·h).

Max liquid flow rate: 1.0~130 m³/(m²·h).

Opening Area Fraction of Gas-Riser Pipes to Tower Cross-Sectional Area (Gas-Riser Opening Ratio): Greater than 25%.

→

→

Trough-Pan Gas and Liquid Distributor Structural Parameters (For Reference Only)

| Tower Internal Diameter |

Bottom Plate Width |

Trough Width | Liquid Deflector Cap Width |

No. of Distribution Holes in Lower Level |

|---|---|---|---|---|

| mm | mm | mm | mm | pc |

| 600 | 570 | 100 | 110 | 26 |

| 700 | 670 | 100 | 110 | 36 |

| 800 | 222 | 110 | 120 | 42 |

| 1000 | 222 | 110 | 120 | 68 |

| 1200 | 222 | 110 | 120 | 100 |

| 1400 | 222 | 110 | 120 | 138 |

| 1600 | 222 | 110 | 120 | 180 |

| 1800 | 222 | 110 | 120 | 236 |

| 2000 | 452 | 110 | 120 | 280 |

| 2200 | 452 | 110 | 120 | 356 |

| 2400 | 452 | 110 | 120 | 424 |

| 2600 | 452 | 110 | 120 | 504 |

| 2800 | 452 | 110 | 120 | 604 |

| 3000 | 452 | 110 | 120 | 708 |

| 3200 | 452 | 110 | 120 | 764 |

| 3400 | 452 | 110 | 120 | 852 |

| 3600 | 452 | 110 | 120 | 986 |

| 3800 | 452 | 110 | 120 | 1064 |

| 4000 | 452 | 110 | 120 | 1170 |

| 4200 | 452 | 110 | 120 | 1308 |

| 4600 | 452 | 110 | 120 | 1602 |

| 5000 | 452 | 110 | 120 | 1832 |

| 5200 | 452 | 110 | 120 | 1992 |

| 5800 | 452 | 110 | 120 | 2568 |

| 6000 | 452 | 110 | 120 | 2740 |

Trough-type gas-liquid distributor has the following features:

(1) Multifunctional: It serves either as a gas-liquid distributor or a liquid distributor (without liquid deflector cap) in packed towers.

(2) Wide Application Range: It can be used in packed towers for processes such as rectification, absorption, desorption, and washing under normal pressure, reduced pressure, and increased pressure in industrial sectors including chemical industry, petrochemical industry, oil refining, light industry, pharmaceutical industry, environmental protection, and atomic energy.

(3) Excellent Performance: It is efficient and versatile; it is anti-clogging and can be used with relatively dirty materials; it has strong performance in preventing entrainment of mist and foam; it distributes gas and liquid uniformly; compared with multi-stage trough-type distributors, it occupies less tower height; it has high operational flexibility, reaching more than 10:1; and the pressure drop of the distributor is relatively low.

Customization is available for special sizes, types, materials and other requirements. Welcome your enquiry!

For your convenience: Cell / Whatsapp: +86 13333087316 Email: ann@chinademister.com