A wire mesh demister is a crucial component in boiler steam drums, designed to remove moisture droplets from the steam flow. Constructed with fine stainless steel or alloy wires woven into a dense mesh structure, it efficiently traps and coalesces water particles, ensuring dry and high-purity steam. Its high separation efficiency, low pressure drop, and corrosion-resistant properties make it ideal for industrial boilers, enhancing system performance and preventing equipment damage caused by wet steam. Installed within the steam drum, it plays a vital role in maintaining optimal steam quality for power generation and process applications.

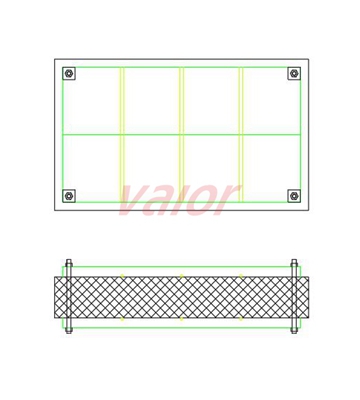

In this case, it is made of SS304 material. The size is 620mm × 370mm × 100mm (mesh thickness). Customization service is available for different material, size, mesh thickness, mesh density, etc.

→

→

The demister has high efficiency, simple structure, light weight, and it is easy for installation and operation.

Wire mesh demister is a device that separates liquid droplets carried in gases (including steam). It is widely used in chemical processes and evaporators, and is also commonly used in boilers. The principle of the demister is that when the mist meets wire mesh together with the steam flow (or air flow), the mist collides with the fine wires of the wire mesh, and the mist (water droplets) immediately gather and expand on the surface of the wire mesh. When the weight of the continuously increasing liquid droplets exceeds the combined force of gas velocity and surface tension of the liquid, the liquid falls.

Welcome to contact Mr. Li An for FREE drawing support and more details!

For your convenience: Cell / Whatsapp: +86 13333087316 Email: ann@chinademister.com